Welcome

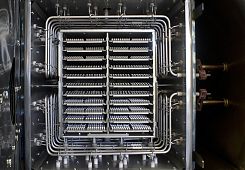

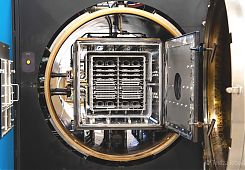

The company Vibrom s.r.o. has a long-term tradition in the field of PIM (powder injection moulding), particularly in processing of ceramic powders. After two years of testing, the company enters the market with processing of metal powders. The company processes advanced ceramic (CIM) and metal (MIM) powders and special plastic materials (e.g. filled with 60% of glass). The technology PIM is modern technological procedure that combines the technology of injection of plastics and conventional powder method.

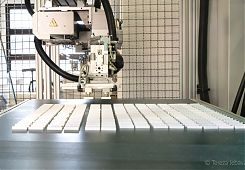

For production of parts the company uses injection presses by Arburg. The injection moulding technology enables production of parts with complicated shapes in big series at much lower costs compared with conventional methods of processing of ceramic materials and metals.

Furthermore, the company is engaged in processing of reactive plastics for production of blast media and in designing of vibration mills.